Magnesium alloy semi continuous casting production line

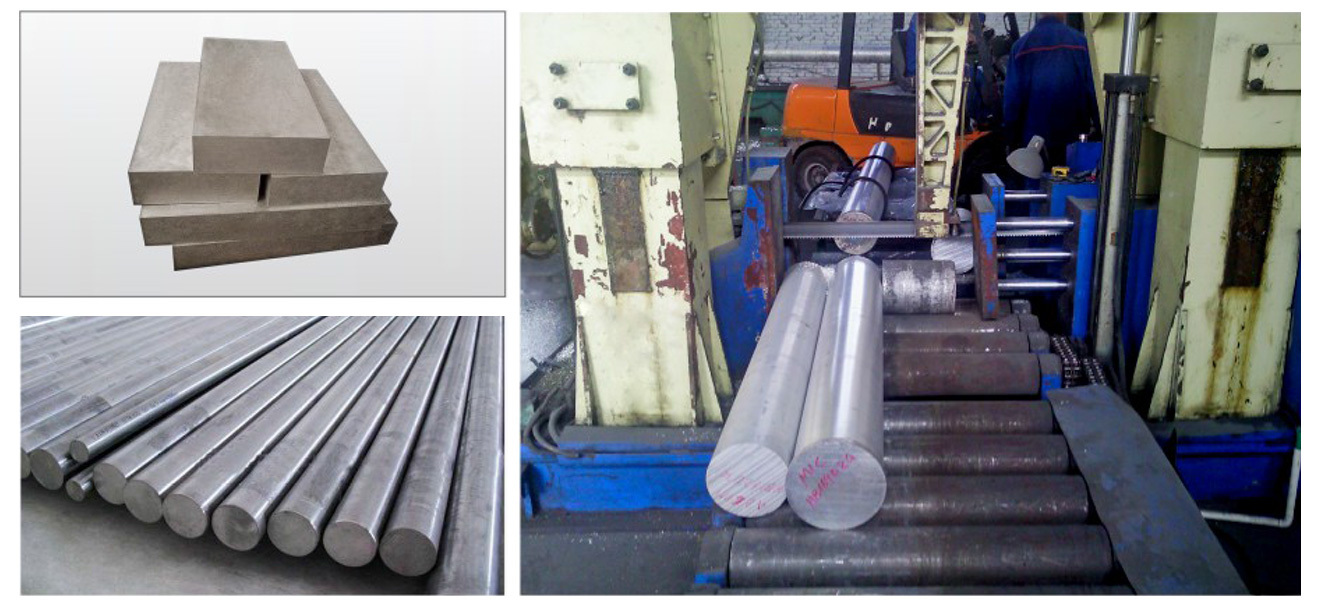

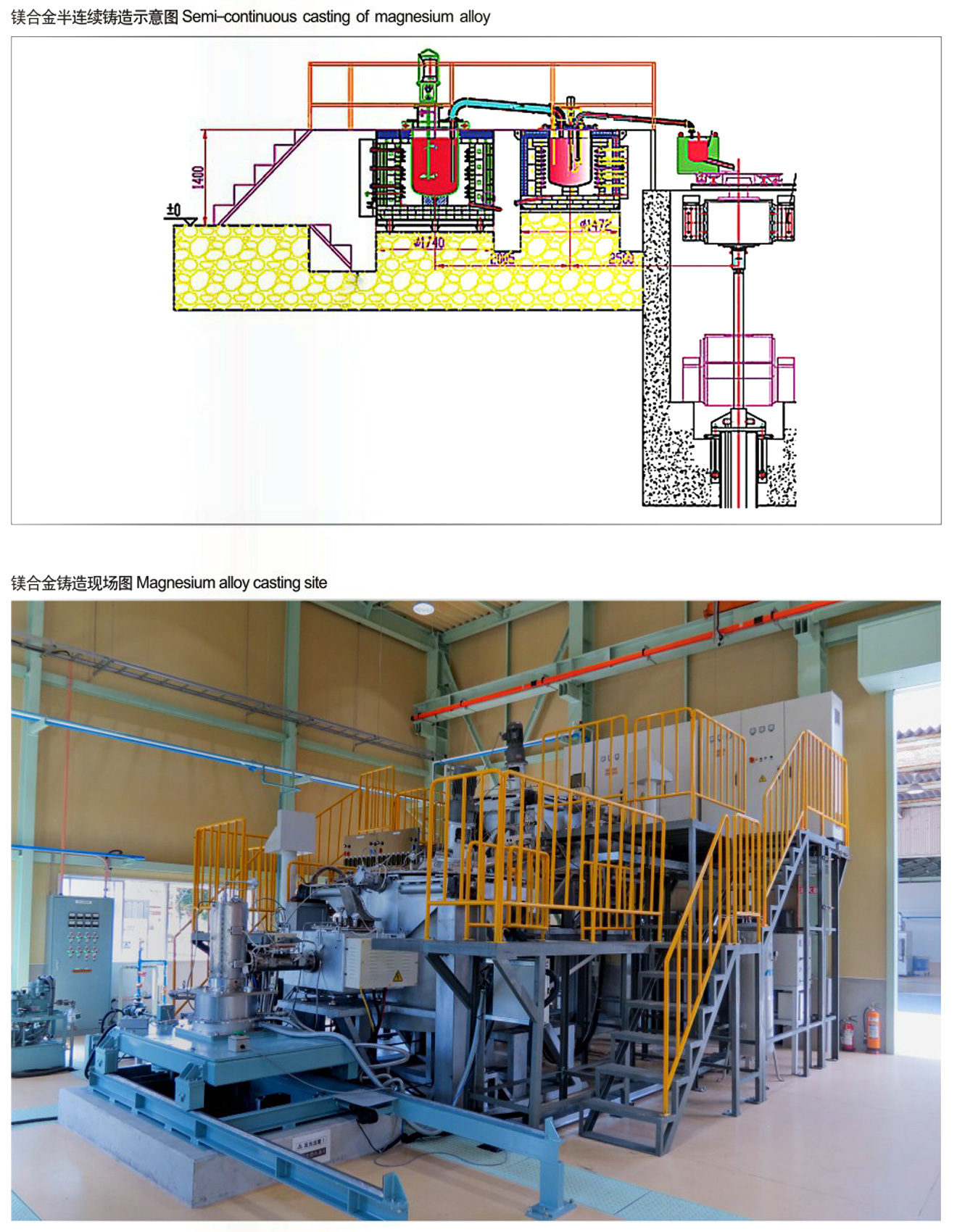

Magnesium alloy semi-continuous casting, is the liquid magnesium alloy liquid automatically transferred to the heat preservation before the liquid tank. The liquid in the front liquid box is controlled by the valve to evenly flow the magnesium liquid into the crystallizer for cooling (circulating water is passed around the crystallizer). At the same time, the traction device of the hydraulic cylinder of the casting machine moves down at a uniform speed, so that the magnesium liquid is drawn down in the form of a solid rod. During the process, the outer circumference of the bar billet is cooled by the water supply water pump of the casting machine, so that the core of the holding billet is solidified quickly and the purpose of producing magnesium bar billet is achieved. The difference between semi-continuous casting and general low pressure or atmospheric pressure casting is that the metal liquid is cooled by circulating water around the mold, and the metal can be solidified quickly. To achieve the purpose of compact crystal structure, no porosity, shrinkage and other casting defects. Because of its excellent characteristics, the semi-continuous casting bar is mostly used as the raw material or sacrificial anode for extruding and rolling profiles.

key word:

Contact Us Message

DESCRIPTION

Product description:

Magnesium alloy semi-continuous casting, is the liquid magnesium alloy liquid automatically transferred to the heat preservation before the liquid tank. The liquid in the front liquid box is controlled by the valve to evenly flow the magnesium liquid into the crystallizer for cooling (circulating water is passed around the crystallizer). At the same time, the traction device of the hydraulic cylinder of the casting machine moves down at a uniform speed, so that the magnesium liquid is drawn down in the form of a solid rod. During the process, the outer circumference of the bar billet is cooled by the water supply water pump of the casting machine, so that the core of the holding billet is solidified quickly and the purpose of producing magnesium bar billet is achieved. The difference between semi-continuous casting and general low pressure or atmospheric pressure casting is that the metal liquid is cooled by circulating water around the mold, and the metal can be solidified quickly. To achieve the purpose of compact crystal structure, no porosity, shrinkage and other casting defects. Because of its excellent characteristics, the semi-continuous casting bar is mostly used as the raw material or sacrificial anode for extruding and rolling profiles.

The commonly used semicontinuous casting machine is divided into hydraulic casting machine and screw driven casting machine, and each has its own advantages. Hydraulic casting machine has high cost and can realize precise control. The screw casting machine has low cost, the driving screw parts need to be replaced regularly due to fragility, and the control accuracy is slightly lower, but it can fully meet the requirements of the casting rod billet.

Operating procedure: Start hydraulic station or screw brake. Set casting parameters (casting speed, length, cooling water flow, etc.) according to the process requirements, remove the sliding trolley, start the lifting platform fast lift ingot head to about + 200mm automatically stop, with compressed air to dry the ingot head. Move the trolley to the casting position, click the lifting platform to send the ingot head into the mold, start the cooling water, and press the button (casting preparation). PLC automatically detects and displays the working current, working voltage, hydraulic system pressure, hydraulic oil temperature, cooling water pressure, cooling water flow, cooling water temperature, operating state of filter valve, operating state of cooling water flow control valve, and working voltage state of each electrical contact.

Open the "casting" button, and the magnesium liquid is pumped from the pump of the holding furnace to the front liquid tank. Through the liquid guide pipe, the magnesium liquid flows into the shitter plate of the core of the mold inside the stabilizer. Open the mold protection air ring of the casting car, adjust the magnesium alloy liquid level in the stabilizer when the magnesium alloy liquid fills the top of the ingot head, press the casting button, the casting machine begins to cast down, and the casting begins.

Related products

这里是标题一h1占位文字

MESSAGE

*Note: Please make sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible